Air Sickness Bags: A Small Item with Big Impact

As the name suggests, air sickness bags are sanitary items provided for passengers who may experience motion sickness during a flight. In reality, however, they are rarely used for that specific purpose. Most passengers end up using them as convenient temporary trash bags.

Though seemingly small, these inflight disposable vomit bags are consumed in massive volumes. For this reason, airlines are increasingly focused on streamlining their design and optimizing costs.

At Shanghai Yiting, a dedicated manufacturer of airline sickness bags, we know that pricing depends on far more than just the shape. In this guide, we’ll break down every design element that affects cost — and help you find the best solution for your airline.

Overview of Customization Factors:

1️⃣ Shape

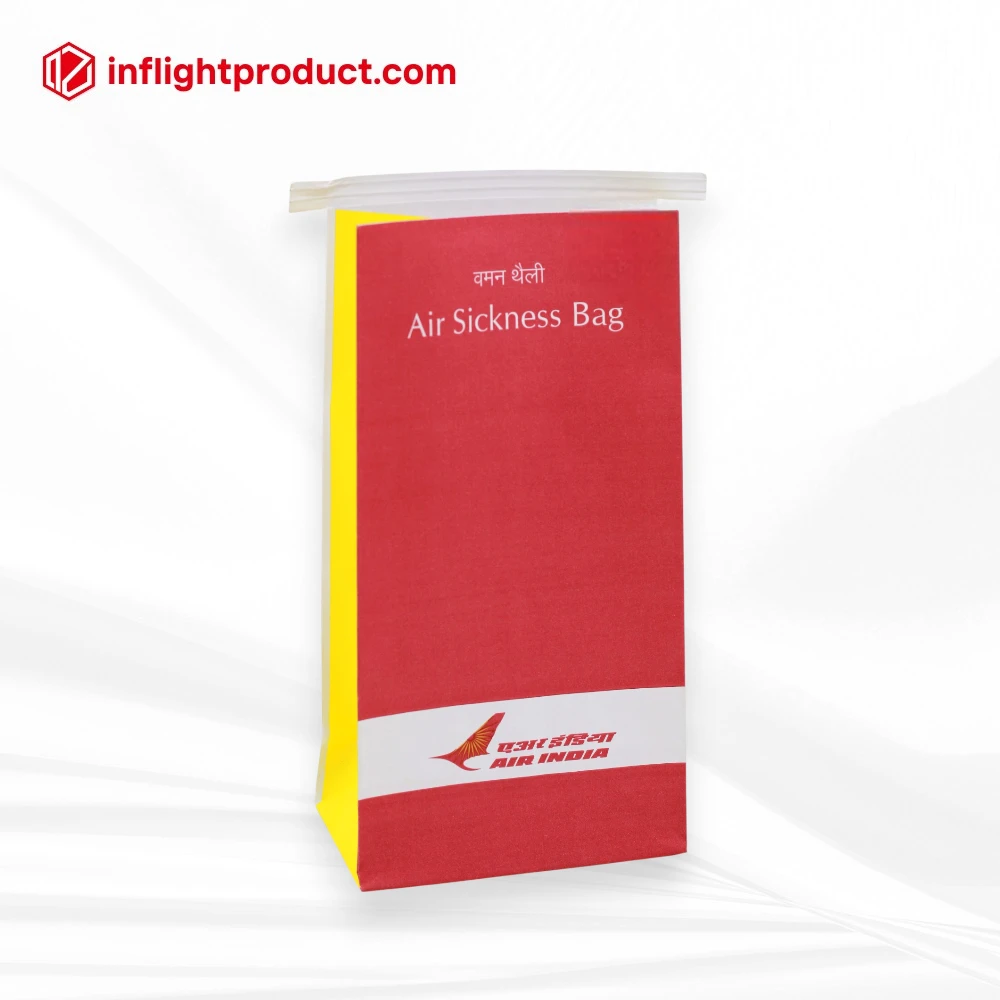

Block Bottom Airsickness Bags

Also Known As: Rectangular Bottom, Square Bottom, Flat Bottom

Structure: Flat bottom that allows the bag to stand upright, offering higher capacity.

Pros:

- Self-standing

- Greater internal volume

- Bottom can serve as an advertising space (some airlines insert the bag upside down into the seat pocket, making the bottom the first visible part)

Cons: higher cost compared to V-shape, taking up more storage space at warehouse

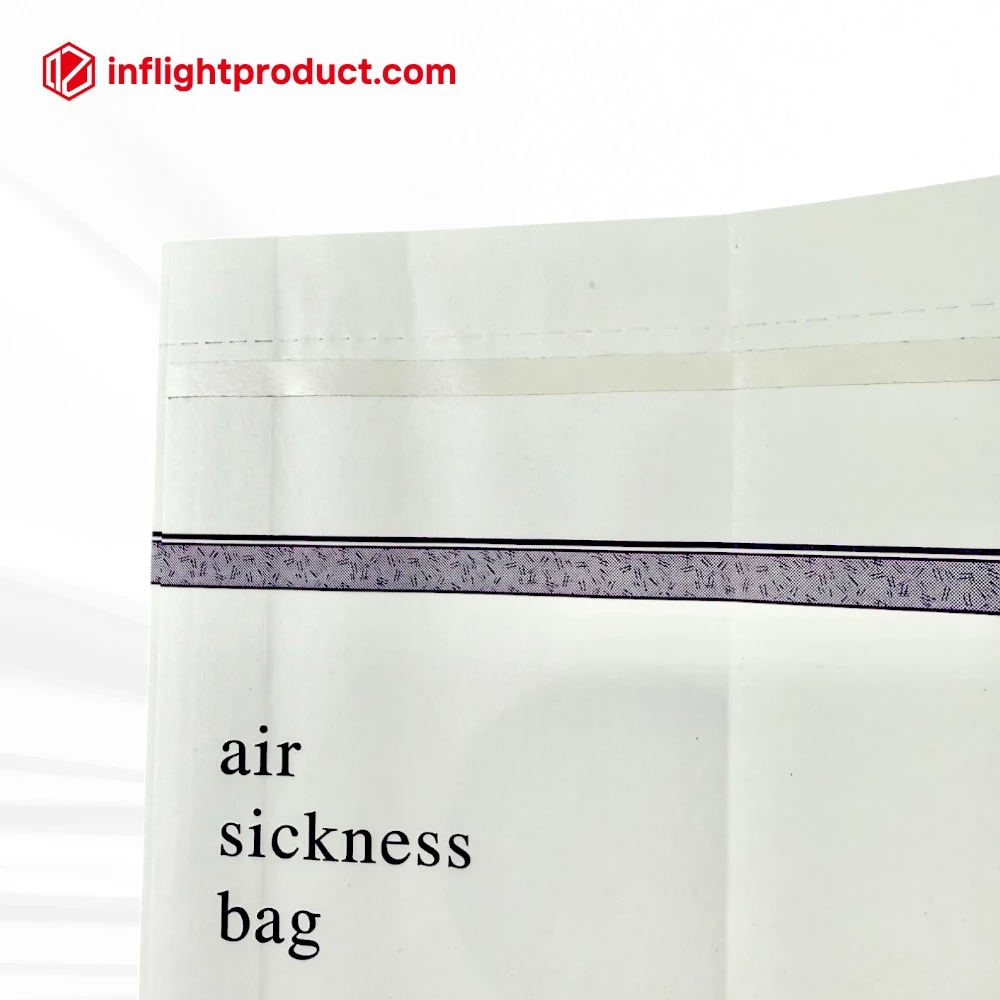

V-Shape Airsickness bags

Also Known As: Pointy Bottom, Sharp Bottom

Structure: V-shaped bottom, folds flat to save storage space

Pros:

- Compact and space-saving at warehouse

- More cost-effective

Cons: Cannot stand upright; lower capacity

Recommendation: Most airlines opt for V-shape bags on regular routes to reduce cost. However, for premium routes or airlines that cater to more sensitive passengers, block bottom bags offer improved comfort and convenience.

2️⃣ Size

Popular Sizes (Customizable):

- Block Bottom: 235×125×80 mm

- V-Shape: 235×125×60 mm or 80 mm

Recommendation: The 235×125×80 mm size is widely accepted. For V-shape bags, 60mm is an alternative option. Larger bags require more material, which increases cost. Some airlines use narrower side widths (e.g., 35 mm) to reduce cost, though this can limit usability and we don’t generally recommend this option unless it has no significant impact on your cabin service experience.

3️⃣ Material

Common Paper Types:

- Offset Paper (Wood-Free Paper): Most common choice. Excellent for printing, affordable, and widely used.

- White Kraft Paper: Stronger, more durable, with a slightly off-white natural tone. Higher cost than offset paper.

- Bamboo Pulp Paper: Eco-friendly air sickness bags option. Natural bamboo tan color, suitable for simple designs.

Grammage Options (Customizable):

- Popular Choice: 60gsm paper + 18gsm PE

- Other Options: 52gsm + 18gsm PE, or even 70gsm + 25gsm PE for premium needs (but rarely seem nowadays).

Recommendation: All paper types to produce airline motion bags are laminated with a PE coating to prevent leaks. Unless otherwise requested, we suggest using the standard 60gsm offset paper with 18gsm PE coating for the motion bags.

4️⃣ Printing

Color Matching: We use Pantone U-series for color matching on matte paper surfaces. Please provide Pantone U codes for best results.

Printing Quality: Offset paper supports full-coverage prints and fine detail. (Other material options are available)

Cost Factors:

- Each color requires a separate printing plate. Fewer colors = lower plate cost

- Plate fees are one-time only unless the design changes

Recommendation: In general, all types of printing can be applied to our airline sick bags. When it comes to printing plate costs, fewer colors usually mean lower expenses.

Do you already have a design ready, or would you like to explore design possibilities with us first?

Feel free to contact our team — we’re happy to discuss your ideas and provide a precise quote for printing costs.

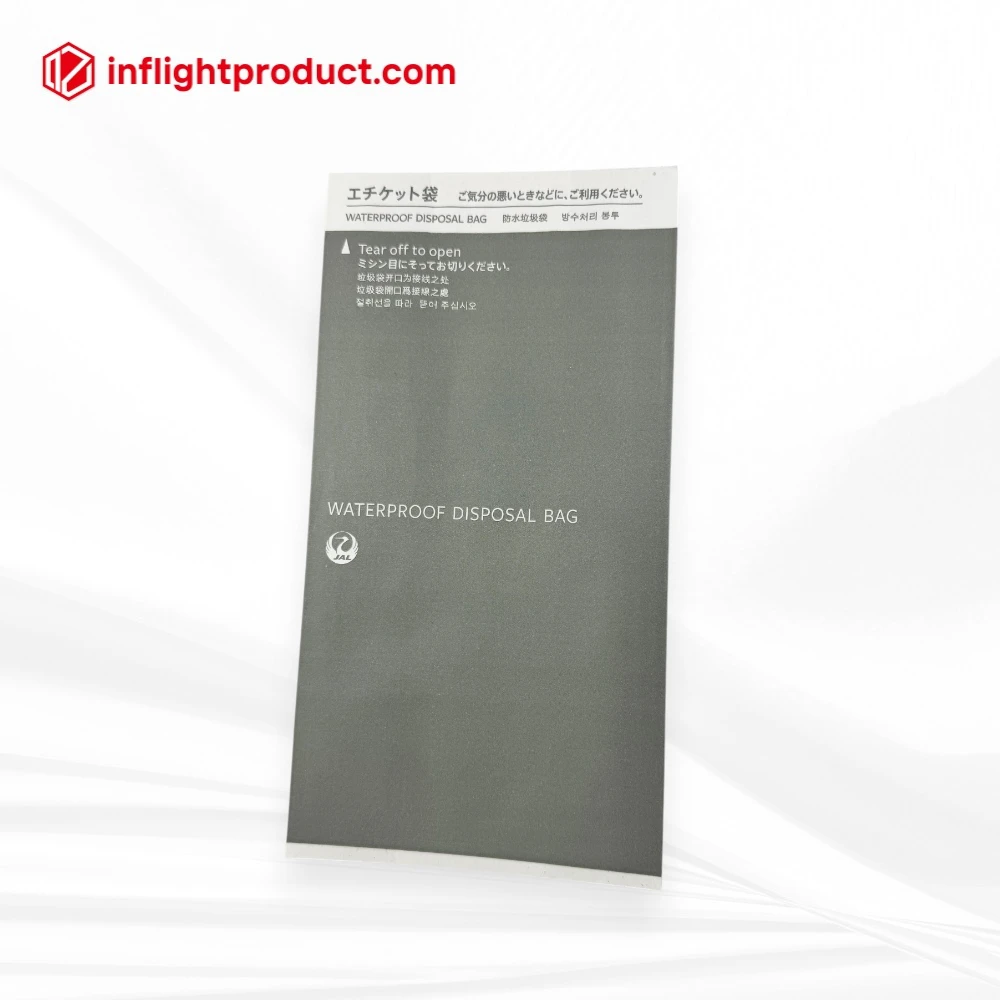

5️⃣ Opening Design

Options:

- Dotted Tear Line: Ensures each bag is unused. Not all airlines require it.

- Serrated Edge: Makes it easier to open the bag. Often used if tear lines are not present.

Recommendation:

- Use either a dotted tear line or serrated edge — not necessary to be both

- If your crew uses upside-down insertion to indicate unused bags, a tear line may be unnecessary

7️⃣ Closure Mechanism

- No Closure: Most cost-effective. Common in many airlines where crew collects the bag immediately after use.

- Back Wire Clip: Popular option; allows simple twist and seal after use

- Double-Sided Tape: Less common; allows seal after use but may not be user-friendly compared to previous one.

- Top Wire Closure: Secure, but significantly increases cost

Recommendation: Back wire tie is the best balance of functionality and cost.

8️⃣ How to Customize the Right Air Sickness Bag for Your Airline

Now back to the question in mind: how to customize airline sickness bags? Consider the following when making your decision:

- Shape: Block bottom provides more capacity; V-shape is cost-effective and getting more and more popular

- Size: Standard 235×125×80 mm for block bottom; 235×125×60/80 mm for V-shape

- Material: 60gsm offset paper + 18gsm PE is a reliable choice

- Printing: Fewer colors reduce costs; Pantone U matching recommended

- Opening: Choose between tear line or serrated edge based on your crew’s SOP

- Closure: Back wire clip is our recommendation but not a must

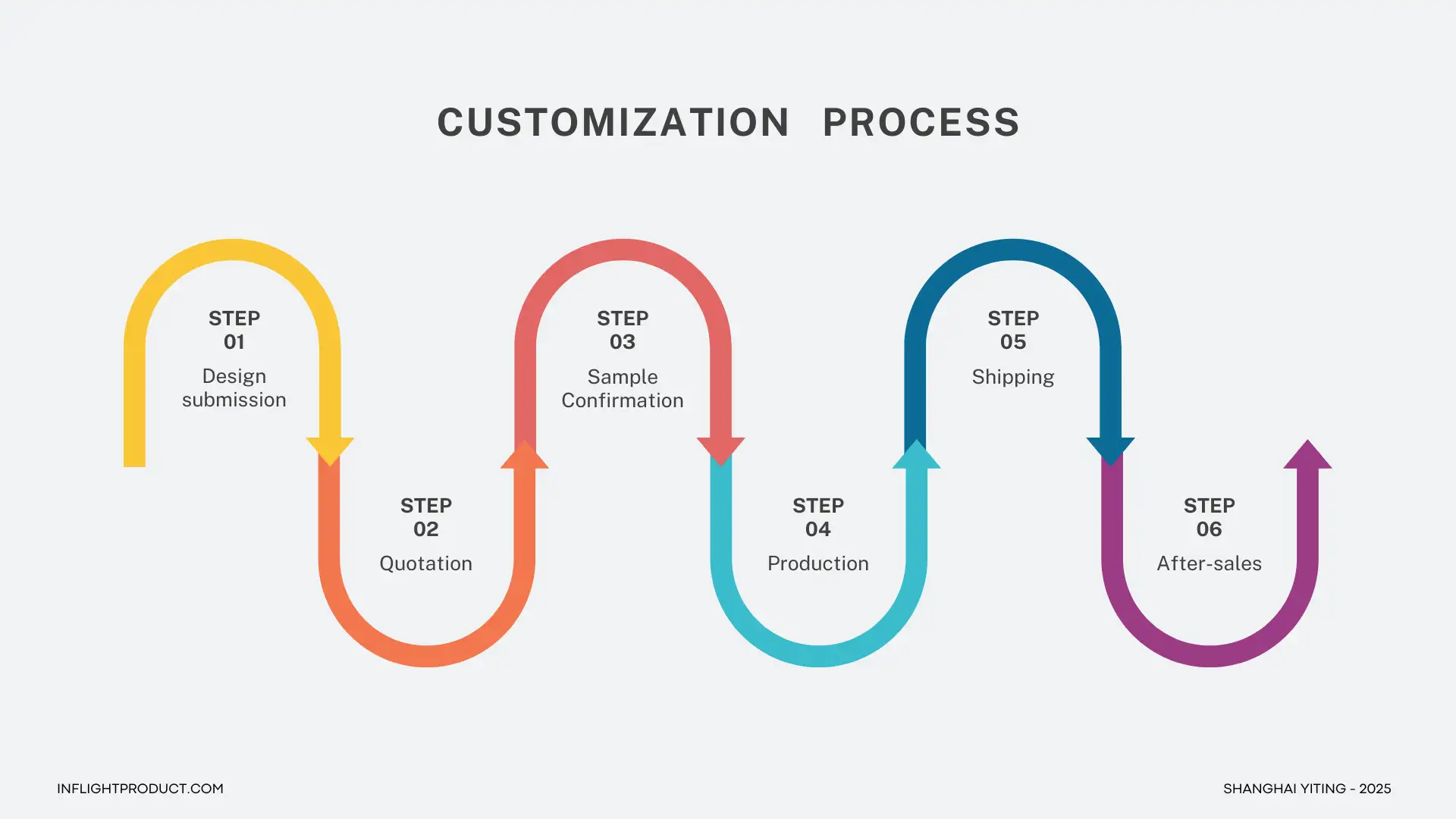

9️⃣ Our Customization Process: Simple and Streamlined

- Design submission: We’ll carefully review your design to assess production feasibility and suggest improvements if needed.

- Quotation: A detailed quote will be provided based on your design, quantity, delivery terms, and any specific requirements.

- Sample confirmation: Reference samples or pre-production (PP) samples will be arranged for your approval, depending on the project scope.

- Production: Standard lead time is approximately 30 days.

- Shipping: We support international delivery and will coordinate logistics according to your shipping preferences.

- After-sales support: Our service doesn’t stop at shipping — we’re here to assist with any follow-up questions or concerns after delivery.

If you encounter design or production challenges, our team is ready to help with practical, production-friendly advice. Talk to us now! WhatsApp Us!

Shanghai Yiting: Your In-Flight Essentials Expert

Looking for a reliable supplier for custom airline sickness bags? Still have questions about material or design? Our experienced team is here to help.

As a trusted air sickness bag manufacturer, vomit bag supplier, and airline inflight products supplier, Shanghai Yiting supports both large and small orders with full customization options for delivering high-quality, customized air sickness bags not only for airlines but also for trains, buses, cars, and other transportation modes. Wherever motion sickness may occur, we can help you create the perfect solution tailored to your needs.

🌐 Explore our products at inflightproduct.com/airsickness-bags/ or contact our sales team for a personalized quote.

This guide is incredibly helpful! We’ve been looking to switch to a more cost-effective sickness bag solution, and the breakdown on material and closure options gave us exactly what we needed to make informed decisions. Appreciate the clarity and transparency!

This guide provides valuable insights into optimizing inflight sickness bags. The focus on cost-effectiveness and customization is particularly useful for airlines. The detailed breakdown of materials and closure options helps in making informed decisions. It’s great to see a supplier offering tailored solutions for various airlines’ needs. Looking forward to reading more tips about sustainable materials and how to improve passenger comfort. Thank you!